-

+65 6908 0869

ELECTRIC HEATING SYSTEM

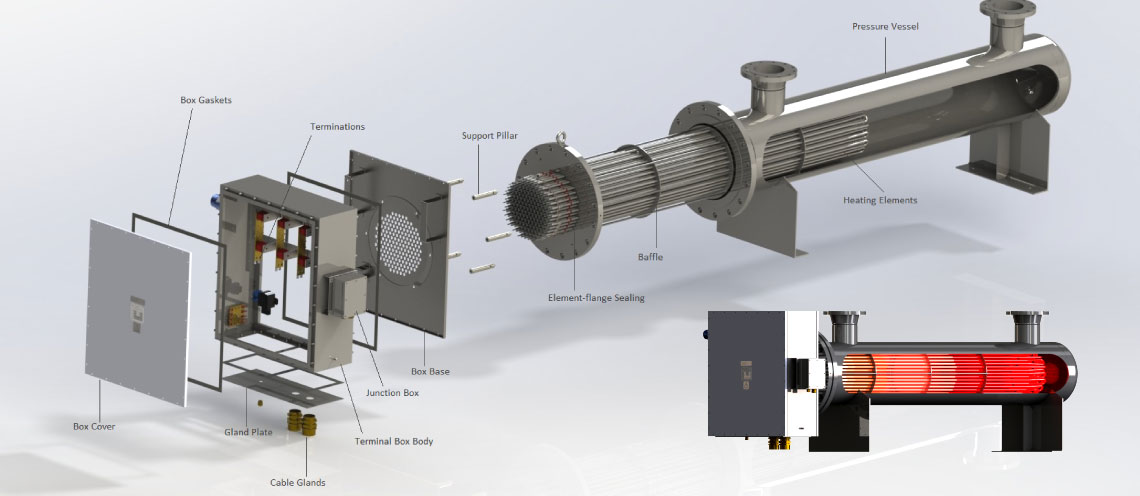

Process Heater

The Electric Process Heater is usually used to provide direct heating to the process. The heating elements are in direct contact with the process to heat up the cold inlet fluids, maximise the heat transfer by optimising baffle design while limiting pressure drop to the outlet nozzle.

With our proprietary software CALCPEX we can customise the design of the process heater and system to meet the process demand with duty regulated by Thyristor and/or Contactor using hardwired or PLC controlled.

APPLICATIONS

- Natural Gas in Gas Transmission Pipeline

- Industrial Gases in Air Separation Unit

- Molecular Sieve Regeneration Heater

- Process Gases in Continuous Catalyst Reforming Unit (CCR)

- Fuel Gas Heater

- Steam Super-heater

- Reboiler Heater in TEG Dehydration System

- Nitrogen Heater

- Seal Gas Heater

- CO2 Heater

TECHNICAL DATA

Certifications

- ATEX and IECEx

Supply Voltage

- Max 690VAC 50/60Hz

Power

- Up to 5000KW in a single unit

Increased Safety (Exe)

- EN IEC 60079-7, 60079-0

II 2 G, Ex eb Gb

II 2 G, Ex eb Gb- T1-T16

- IIA/IIB/IIC

- IP66

Flameproof (Exd)

- EN IEC 60079-1, 60079-0

EN IEC 60079-31  II 2 G/D, Ex db Gb

II 2 G/D, Ex db Gb

Ex tb Db- T1-T6

T85-T450°C - IIA/IIB/IIC

IIIC - IP66

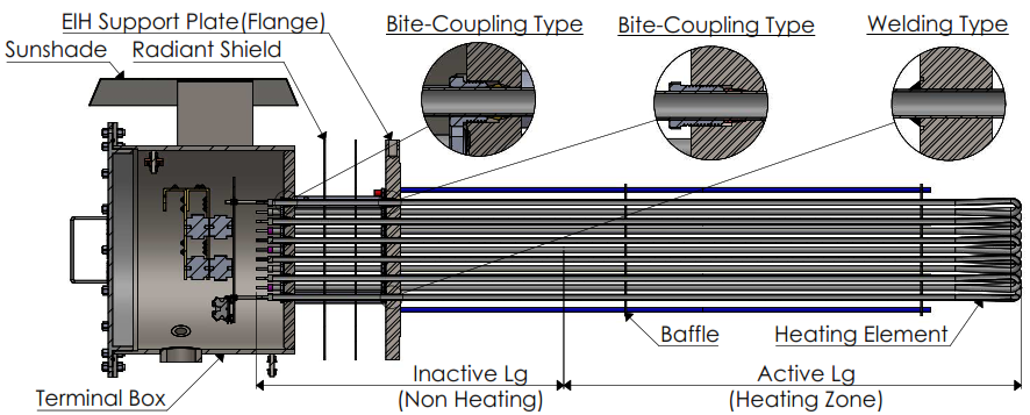

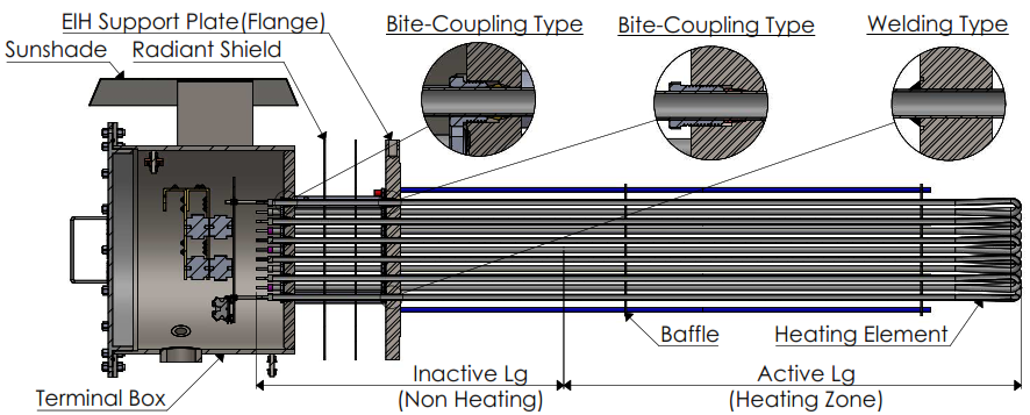

HEATER CONSTRUCTIONS

Heating Element

- Tubular Heating element with NiCr 80/20 resistive heating wire compacted with MgO

- Element diameter: 12.5mm, 16mm

- Element sheath material: Incoloy 800, 825, SS321, SS304, SS316, Titanium and others

Heater Flange

- Also known as EIH Support Plate

- Design to ASME Appendix 41

Over-temperature Protection

- Element over-temperature protection

- T-class protection

- Terminal Box over-temperature protection (optional)

Pressure Sealing

- Bite-coupling, strength weld

or bracing

Terminal Box

- Exe – Standard SS316 or painted mild steel

- Exd – Standard Carbon Steel or SS on request

HEATING ELEMENT SELECTION

Items

- Heat Flux

Considerations

- Process medium

- Client Specifications

(e.g. DEP, PTS)

Typical

- TEG: 2.2w/cm2,

- Fuel Gas: 2-7w/cm2

- Element Material

- Temperature exposure

- NACE

- Incoloy 800,

- SS304, SS321

- Incoloy 825

ELEMENT TUBE CONSTRUCTION

Pressure Rating

- 150lbs

- 300lbs

- 600lbs

- 900lbs and above

<150 Deg. C

- Welded

- Welded

- Welded

- Seamless

150-300 Deg. C

- Welded

- Welded

- Seamless

- Seamless

>300 Deg. C

- Seamless

- Seamless

- Seamless

- Seamless

Tube Wall thickness recommendation

Welded tube: min 1.0mm, Seamless tube: min 1.25mm

Disclaimer: Above table is derived based on DFINITI’s past experience in dealing with various processes, applications and clients’ specifications and requirements, and it is merely for reference. Specific clients or process licensors may specify seamless tube regardless of pressure and temperature rating. Seamless tube is recommended for lethal services application. DFINITI shall not be responsible or held liable for any losses and damages resulting from adopting the above recommendations without further review of the actual and specific requirement or agreement

TANK IMMERSION HEATER

Immersion heating is used to heat up and/or maintain the medium in the tank to reduce viscosity at desired temperature for ease of flowing or pumping out of the medium. The medium can be in the form of condensate, bitumen, chemical or any sludge collected in the sump tank.

WITHDRAWABLE HEATER (CARTRIDGE TYPE)

Besides the conventional design, the heater can be designed with withdrawable elements which allow replacement of heating elements without draining the tank to offer quicker turnaround time. This is also known as online replacement.

We put much thoughts into improving the cartridge heater design that shortens the downtime when replacing the elements. The cartridge heater design allows online replacement without having to drain the tank. It helps to reduce downtime and minimise disruptions. With DFINITI’s improved design, we further cut down the downtime by more than 50%. The key lies in the type of seal which provides the necessary protection. It is concurrently easily removed and accessed, especially when replacing elements at the centre of the heater.

L-SHAPE AND OTHER SHAPES OF HEATER

For underground tank design where the only access is from the top, an L-shape or a dog-leg shape heater can be provided.

APPLICATIONS

- Condensate Heater

- Separator Tank Heating

- Crude Oil Heater

- Produced Water Heater

- Caustic Water in CIP Tank

- Bitumen Heating in Storage Tank

- Thermal Liquids Heating

TECHNICAL DATA

Certifications

- ATEX and IECEx

Supply Voltage

- Max 690VAC 50/60Hz

Power

- Up to 5000KW in a single unit

Increased Safety (Exe)

- EN IEC 60079-7, 60079-0

II 2 G, Ex eb Gb

II 2 G, Ex eb Gb- T1-T16

- IIA/IIB/IIC

- IP66

Flameproof (Exd)

- EN IEC 60079-1, 60079-0

EN IEC 60079-31  II 2 G/D, Ex db Gb

II 2 G/D, Ex db Gb

Ex tb Db- T1-T6

T85-T450°C - IIA/IIB/IIC

IIIC - IP66

HEATER CONSTRUCTION

Heating Element

- Tubular Heating element with NiCr 80/20 resistive heating wire compacted with MgO

- Element diameter: 12.5mm, 16mm

- Element sheath material: Incoloy 800, 825, SS321, SS304, SS316, Titanium and others

Heater Flange

- Also known as EIH Support Plate

- Design to ASME Appendix 41

Over-temperature Protection

- Element over-temperature protection

- T-class protection

- Terminal Box over-temperature protection (optional)

Pressure Sealing

- Bite-coupling, strength weld

or bracing

Terminal Box

- Exe – Standard SS316 or painted mild steel

- Exd – Standard Carbon Steel or SS on request

HEATING ELEMENT SELECTION

Items

- Heat Flux

Considerations

- Process medium

- Client Specifications

(e.g. DEP, PTS)

Typical

- TEG: 2.2w/cm2,

- Fuel Gas: 2-7w/cm2

- Element Material

- Temperature exposure

- NACE

- Incoloy 800,

- SS304, SS321

- Incoloy 825

ELEMENT TUBE CONSTRUCTION

Pressure Rating

- 150lbs

- 300lbs

- 600lbs

- 900lbs and above

<150 Deg. C

- Welded

- Welded

- Welded

- Seamless

150-300 Deg. C

- Welded

- Welded

- Seamless

- Seamless

>300 Deg. C

- Seamless

- Seamless

- Seamless

- Seamless

Tube Wall thickness recommendation

Welded tube: min 1.0mm, Seamless tube: min 1.25mm

Disclaimer: Above table is derived based on DFINITI’s past experience in dealing with various processes, applications and clients’ specifications and requirements, and it is merely for reference. Specific clients or process licensors may specify seamless tube regardless of pressure and temperature rating. Seamless tube is recommended for lethal services application. DFINITI shall not be responsible or held liable for any losses and damages resulting from adopting the above recommendations without further review of the actual and specific requirement or agreement

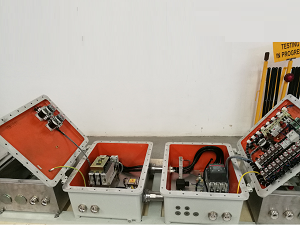

CONTROL PANEL

A Control Panel is installed to the Electric Process Heater to operate the heater throughout the lifespan of the system. It is therefore important and critical that the Control Panel is designed not only to achieve functional purposes and protection but also smooth operations to prevent disruption to the process and any other undesirable incidents.

There are two main factors in designing the Control System

Types of Control

- On/Off or 0-100% load control

- Single stage or multiple stages

Areas of Installation

- Safe area

- Hazardous area

Heaters used in process heating are usually designed to Thyristor controlled which is capable of modulating load from 0-100% on heater output. Due to high heat dissipation from Thyristor switching, the panel is normally housed indoor to avoid excess heating of heat duty within the panel.

Forced fan ventilation is included as a standard for the Thyristor panel. For outdoor installations where the heater duty is big and with high ambient temperature, air-conditioner may be used if forced fan ventilation is insufficient.

TYPICAL THYRISTOR CONTROL PANEL

Load Control

- Thyristor (aka SCR)

Stage Control

- Single stage or multiple stages control

Control Logic

- Hardwired or PLC

Functions

- Heater On/Off

- Duty Control

- Local (manual) or Remote (auto)

- Duty Selector

- Trip Reset

Type of Protection

- Over-current

- Earth fault

- Panel over-temperature

- Heating element over-temperature

- Thyristor over-temperature

- ESD

- T-class (by design or sensor)

- Terminal Box over-temperature (optional)

- Shell temperature (optional)

- Other protections are available on request.

Installation

- IP Rating

- Cooling

- MOC

Indoor

- IP42 or IP44

- Forced Fan

- Painted Mild Steel

Outdoor

- IP54

- Forced Fan or Air-conditioner

- Painted Mild Steel or SS

For installation in hazardous areas, the Control Panel is designed with Exd Ex-proof enclosure for small heater load and/or Contactor controlled where heat dissipation is minimum. These are usually for local Control Panel use in tank immersion heaters.

Other than Exd panel, purged panel Ex’p’ can be offered for installation in a hazardous area.

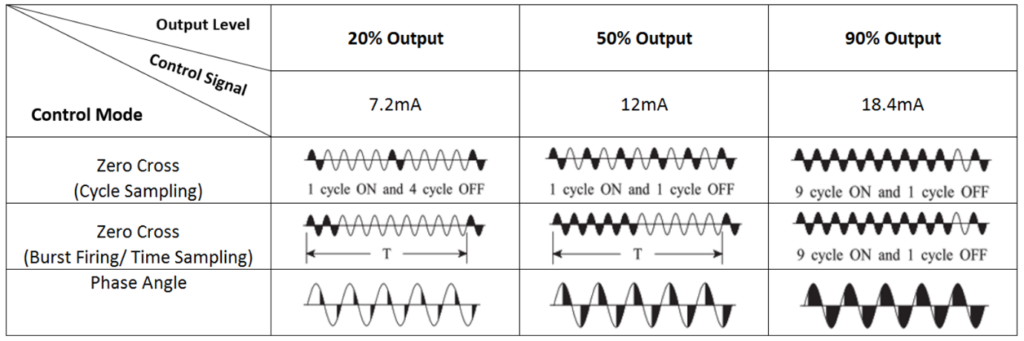

MODES OF THYRISTOR FIRING

Subject to switching duty and the overall electrical system, there are basically three types of firing modes:

- Zero Cross-over, Single Cycle Firing

- Zero Cross-over, Burst Firing

- Phase Angle Firing

Notes:

1. Phase angle control is not preferred as it generates harmonic. If phase angle is used, Active Harmonic Filter (AHF) shall be used to filter the unwanted harmonic.

2. As the control mode may affect the entire electric system especially a large heater duty, it is advisable to consult DFINITI for the more suitable control mode to suit specific design.

This post is also available in:

简体中文 (Chinese (Simplified))

简体中文 (Chinese (Simplified))  Русский (Russian)

Русский (Russian)  Português (Portuguese (Brazil))

Português (Portuguese (Brazil))