-

+65 6908 0869

电加热系统

过程加热器

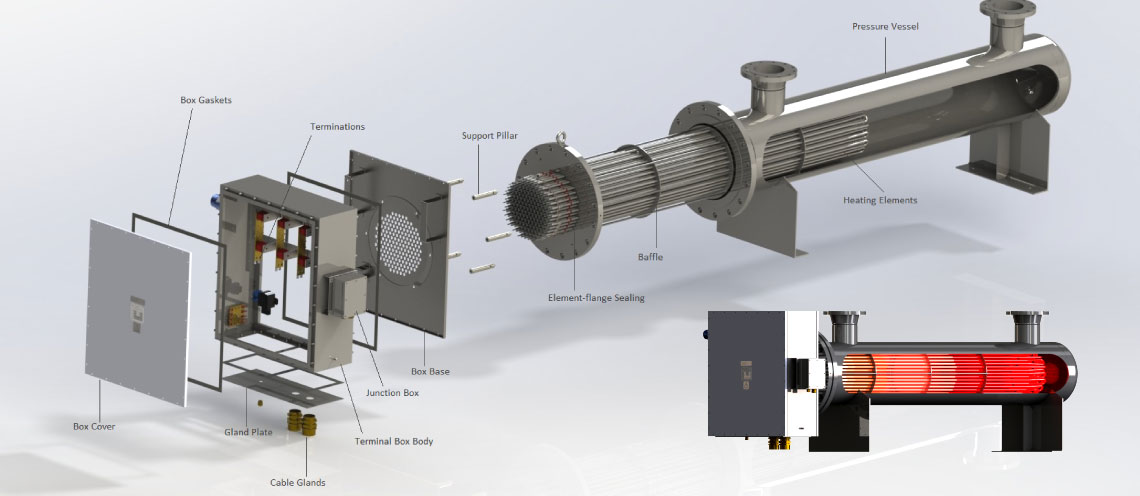

电过程加热器通常用于为过程提供直接加热. 加热元件与过程直接接触以加热冷入口流体,通过优化挡板设计最大限度地提高热传递,同时限制出口喷嘴的压降.

使用我们的专有软件 CALCPEX 和其他专业设计软件, 我们可以定制过程加热器和系统的设计,以满足由晶闸管和/或接触器使用硬接线或 PLC 控制的占空比的过程需求.

应用

- 输气管道中的天然气

- 空分装置中的工业气体

- 分子筛再生加热器

- 连续催化剂重整装置 (CCR) 中的工艺气体

- 燃气加热器

- 蒸汽过热器

- TEG脱水系统中的再沸器加热器

- 氮气加热器

- 密封气体加热器

- 二氧化碳加热器

技术数据

认证

- ATEX 和 IECEx

供电电压

- 最大 690VAC 50/60Hz

力量

- 单台高达 5000KW

增强安全性 (Exe)

- EN IEC 60079-7、60079-0

II 2 G, Ex eb Gb

II 2 G, Ex eb Gb- T1-T16

- IIA/IIB/IIC

- IP66

隔爆(Exd)

- EN IEC 60079-1、60079-0

EN IEC 60079-31  II 2 G/D, Ex db Gb

II 2 G/D, Ex db Gb

Ex tb Db- T1-T6

T85-T450°C - IIA/IIB/IIC

ⅢC - IP66

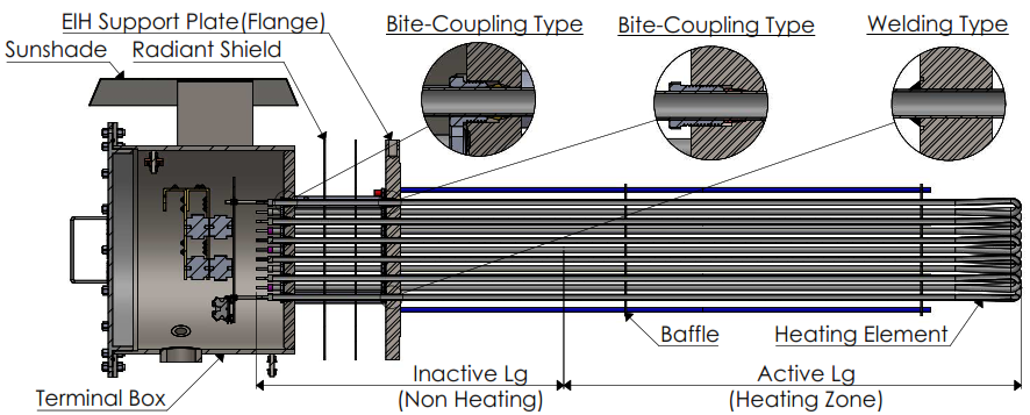

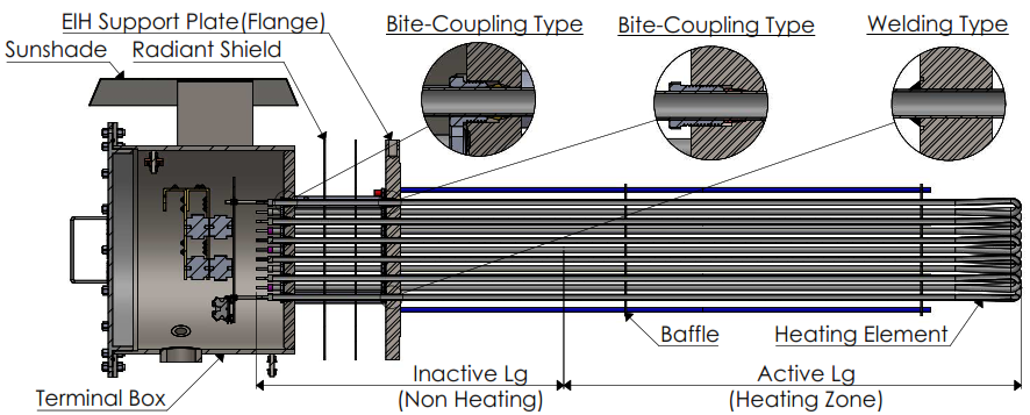

加热器结构

加热元件

- 管状加热元件,采用 MgO 压实的 NiCr 80/20 电阻加热丝

- 元件直径:12.5mm、16mm

- 元素护套材料:Incoloy 800、825、SS321、SS304、SS316、钛等

加热器法兰

- 也称为 EIH 支撑板

- 按照 ASME 附录 41 进行设计

过温保护

- 元件过温保护

- T 级防护

- 接线盒过温保护(可选)

压力密封

- 咬合连接,强度焊接

或支撑

接线盒

- Exe – 标准 SS316 或涂漆低碳钢

- Exd – 根据要求提供标准碳钢或 SS

加热元件选择

项目

- 热通量

注意事项

- 处理介质

- 客户规格

(例如 DEP、PTS)

典型

- TEG:2.2w/cm2,

- 燃料气:2-7w/cm2

- 元素材质

- 温度暴露

- NACE

- Incoloy 800,

- SS304、SS321

- Incoloy 825

元件管结构

压力等级

- 150 磅

- 300 磅

- 600 磅

- 900 磅及以上

<150 度

- 焊接

- 焊接

- 焊接

- 无缝

150-300 度。

- 焊接

- 焊接

- 无缝

- 无缝

>300 度。

- 无缝

- 无缝

- 无缝

- 无缝

管壁厚度推荐

焊管:最小1.0mm,无缝管:最小1.25mm

免责声明:上表是根据DFINITI过往处理各种流程、应用和客户规格要求的经验得出的,仅供参考。无论压力和温度等级如何,特定客户或工艺许可方都可以指定无缝管。推荐用于致命服务应用的无缝管。未经进一步审查实际和具体要求或协议,DFINITI 不对因采用上述建议而造成的任何损失和损害负责

水槽浸入式加热器

浸入式加热用于加热和/或保持罐中的介质以降低所需温度下的粘度,以便于从介质中流出或泵出. 介质可以是冷凝水、沥青、化学品或收集在集水池中的任何污泥.

抽出式加热器(筒式)

除了传统的设计,加热器可以设计有可抽出的元件,这样可以在不排空水箱的情况下更换加热元件,以提供更快的周转时间. 这也称为在线更换.

我们花了很多心思改进筒式加热器设计,以缩短更换元件时的停机时间。 筒式加热器设计允许在线更换而无需排空水箱。 它有助于减少停机时间并最大限度地减少中断。 通过 DFINITI 的改进设计,我们进一步减少了 50% 以上的停机时间。 关键在于提供必要保护的密封类型。 它同时易于拆卸和访问,尤其是在更换加热器中心的元件时.

L型和其他形状的加热器

对于只能从顶部进入的地下储罐设计,可以提供 L 形或狗腿形加热器.

APPLICATIONS

- Condensate Heater

- Separator Tank Heating

- Crude Oil Heater

- Produced Water Heater

- Caustic Water in CIP Tank

- Bitumen Heating in Storage Tank

- Thermal Liquids Heating

TECHNICAL DATA

Certifications

- ATEX and IECEx

Supply Voltage

- Max 690VAC 50/60Hz

Power

- Up to 5000KW in a single unit

Increased Safety (Exe)

- EN IEC 60079-7, 60079-0

II 2 G, Ex eb Gb

II 2 G, Ex eb Gb- T1-T16

- IIA/IIB/IIC

- IP66

Flameproof (Exd)

- EN IEC 60079-1, 60079-0

EN IEC 60079-31  II 2 G/D, Ex db Gb

II 2 G/D, Ex db Gb

Ex tb Db- T1-T6

T85-T450°C - IIA/IIB/IIC

IIIC - IP66

HEATER CONSTRUCTION

Heating Element

- Tubular Heating element with NiCr 80/20 resistive heating wire compacted with MgO

- Element diameter: 12.5mm, 16mm

- Element sheath material: Incoloy 800, 825, SS321, SS304, SS316, Titanium and others

Heater Flange

- Also known as EIH Support Plate

- Design to ASME Appendix 41

Over-temperature Protection

- Element over-temperature protection

- T-class protection

- Terminal Box over-temperature protection (optional)

Pressure Sealing

- Bite-coupling, strength weld

or bracing

Terminal Box

- Exe – Standard SS316 or painted mild steel

- Exd – Standard Carbon Steel or SS on request

HEATING ELEMENT SELECTION

Items

- Heat Flux

Considerations

- Process medium

- Client Specifications

(e.g. DEP, PTS)

Typical

- TEG: 2.2w/cm2,

- Fuel Gas: 2-7w/cm2

- Element Material

- Temperature exposure

- NACE

- Incoloy 800,

- SS304, SS321

- Incoloy 825

ELEMENT TUBE CONSTRUCTION

Pressure Rating

- 150lbs

- 300lbs

- 600lbs

- 900lbs and above

<150 Deg. C

- Welded

- Welded

- Welded

- Seamless

150-300 Deg. C

- Welded

- Welded

- Seamless

- Seamless

>300 Deg. C

- Seamless

- Seamless

- Seamless

- Seamless

Tube Wall thickness recommendation

Welded tube: min 1.0mm, Seamless tube: min 1.25mm

Disclaimer: Above table is derived based on DFINITI’s past experience in dealing with various processes, applications and clients’ specifications and requirements, and it is merely for reference. Specific clients or process licensors may specify seamless tube regardless of pressure and temperature rating. Seamless tube is recommended for lethal services application. DFINITI shall not be responsible or held liable for any losses and damages resulting from adopting the above recommendations without further review of the actual and specific requirement or agreement

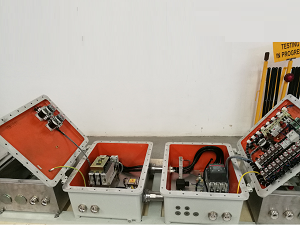

控制面板

控制面板安装在电气过程加热器上,以在系统的整个生命周期内操作加热器。 因此,重要且关键的是,控制面板的设计不仅要实现功能目的和保护,还要使操作顺畅,以防止过程中断和任何其他不良事件.

设计控制系统有两个主要因素

控制类型

- 开/关或 0-100% 负载控制

- 单级或多级

安装区域

- 安全区

- 危险地带

过程加热中使用的加热器通常设计为可控硅控制,能够在加热器输出上调节 0-100% 的负载。 由于晶闸管开关的高散热,面板通常安装在室内,以避免面板内的热负荷过度加热.

强制风扇通风是晶闸管面板的标准配置。 对于暖气负荷大、环境温度高的室外安装,如果强制风扇通风不足,可以使用空调.

TYPICAL THYRISTOR CONTROL PANEL

Load Control

- Thyristor (aka SCR)

Stage Control

- Single stage or multiple stages control

Control Logic

- Hardwired or PLC

Functions

- Heater On/Off

- Duty Control

- Local (manual) or Remote (auto)

- Duty Selector

- Trip Reset

Type of Protection

- Over-current

- Earth fault

- Panel over-temperature

- Heating element over-temperature

- Thyristor over-temperature

- ESD

- T-class (by design or sensor)

- Terminal Box over-temperature (optional)

- Shell temperature (optional)

- Other protections are available on request.

Installation

- IP Rating

- Cooling

- MOC

Indoor

- IP42 or IP44

- Forced Fan

- Painted Mild Steel

Outdoor

- IP54

- Forced Fan or Air-conditioner

- Painted Mild Steel or SS

For installation in hazardous areas, the Control Panel is designed with Exd Ex-proof enclosure for small heater load and/or Contactor controlled where heat dissipation is minimum. These are usually for local Control Panel use in tank immersion heaters.

Other than Exd panel, purged panel Ex’p’ can be offered for installation in a hazardous area.

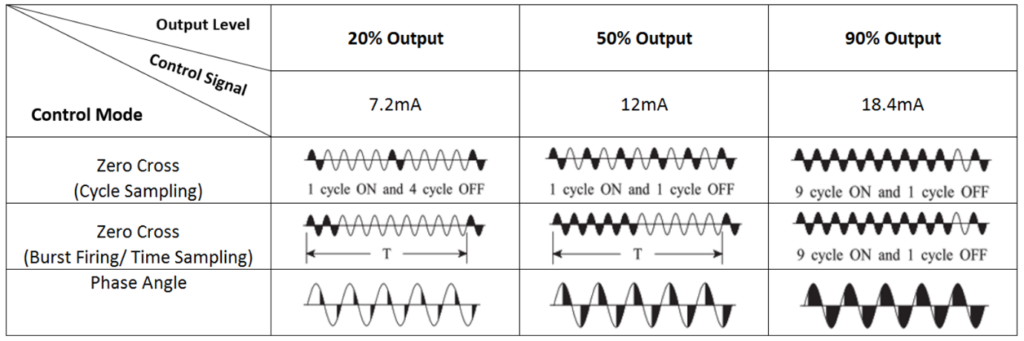

MODES OF THYRISTOR FIRING

Subject to switching duty and the overall electrical system, there are basically three types of firing modes:

- Zero Cross-over, Single Cycle Firing

- Zero Cross-over, Burst Firing

- Phase Angle Firing

Notes:

1. Phase angle control is not preferred as it generates harmonic. If phase angle is used, Active Harmonic Filter (AHF) shall be used to filter the unwanted harmonic.

2. As the control mode may affect the entire electric system especially a large heater duty, it is advisable to consult DFINITI for the more suitable control mode to suit specific design.

This post is also available in:

English (英语)

English (英语)  Русский (俄语)

Русский (俄语)  Português (葡萄牙语(巴西))

Português (葡萄牙语(巴西))